Copyright 2012 neutronsources.org | All rights reserved. | Powered by FRM II | Imprint / Privacy Policy

Led by France, Italy and the UK, ESS is Pushing Accelerator Technology to its Limits

Accelerator Project. In the final and major stages of acceleration before contact with the Target, the proton beam energy of the ESS Accelerator will reach 2.0 GeV, making it the most powerful linear proton accelerator ever built. France’s national Atomic and Alternative Energies Commission, CEA, is guiding the design, production and testing of the superconducting radio-frequency elliptical cryomodules that make this possible.

Date: 12/02/2016

Source: https://europeanspallationsource.se/

LUND and SACLAY—Building the European Spallation Source (ESS) Accelerator requires the expertise of no fewer than 26 partner institutions executing 17 work packages across Europe. One of the largest of these work packages includes nearly half the length of the linear accelerator (linac), five institutions in four European countries, and 20 percent of the Accelerator construction budget. This is Accelerator Systems Work Package 5 (WP05).

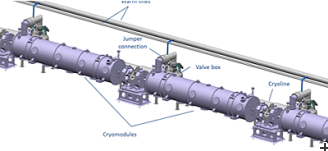

Working in close collaboration with one another, the members of WP05 have the responsibility to produce nine medium-beta and 21 high-beta superconducting radio-frequency (SRF) elliptical cryomodules for installation in the ESS Accelerator tunnel in Lund, Sweden. Once installed in-line the cryomodules will run 256 meters and provide nearly 90 percent of the beam acceleration. The tunnel structure is expected to be completed next month, with partial access for installations scheduled for September.

“The elliptical part of the Linac provides the bulk of the beam energy available for neutron production and is the part that will qualify the ESS Accelerator as the most powerful proton source in the world when ready. Work Package 5 is a key to the success of ESS,” says Mats Lindroos, Head of the Accelerator Division at ESS.

‘A Human Adventure’

Work Package 5 is being executed by five institutions: CEA Saclay’s research institute, IRFU; the Orsay lab of CNRS, the French National Centre for Scientific Research; the UK’s Science & Technology Facilities Council (STFC) accelerator science facility in Daresbury; INFN-LASA, Italy’s national accelerator and applied superconductivity laboratory in Milan; and the ESS Accelerator Division. IRFU scientist Pierre Bosland is the Work Package Leader for WP05, assisted by Deputy Work Package Leader Christine Darve, a senior scientist at ESS.

The work is distributed as In-Kind Contributions to ESS from the national institutes on behalf of France, Italy and the UK. The prototypes for both cryomodule types, high-beta and medium-beta, are being fully developed and tested by CEA Saclay and IPN Orsay. IRFU—the French national Institute for Research on the Fundamental Laws of the Universe—will provide all cryomodule components except the cavities, and will include the final assembly of the full cryomodule units in a clean room. LASA will provide the medium-beta cavities of the series, with Daresbury providing the high-beta cavities. Finally, ESS will perform the crucial radio frequency (RF) power tests of the cryomodules before installation. ESS is coordinating the overall SRF effort in order to meet the general ESS Accelerator requirements, as well as to ensure smooth component integration during installation in the tunnel.

“This is a perfect illustration of the state-of-the-art competencies available all across Europe,” says ESS Technical Director Roland Garoby, “and how powerful they can be when they come together in a project like ESS.

“ESS is a great project, a fantastic scientific and technical adventure, but most of all it is a human adventure,” adds Philippe Chomaz, the former Director of IRFU and now the first Executive Scientific Director of the newly formed CEA Basic Research Division, overseeing 15 French research institutes, including IRFU. Chomaz was succeeded at IRFU by Anne-Isabelle Etienvre in January. “We are proud and happy to work together toward a common goal: get the first neutrons as soon as possible and build together the greatest neutron source in the world.”

Unprecedented Power from Dependable Technologies

Aside from the large coordination effort, the real challenge for this diverse group is to take existing linac superconducting technology to its upper limit in order to meet the high-power specifications for the ESS Linac. The standard technologies that are the components of an ESS elliptical cryomodule are not ordinarily pushed so far in terms of both performance and quality.

In order to ensure reliable performance of the Linac, the team must optimise and adapt the standard technology each step of the way—from the design, fabrication, and chemical treatments applied to the niobium metal cavities, to the diagnostic means and methods, machine toolings, and the cryomodule assembly process itself.

“ESS performance requirements are very high, at the limit of what can be achieved by prototypes. So we are using standard and proven technologies as much as possible,” explains Bosland. “The accelerating cavities are standard elliptical cavities made out of high-purity niobium. We are using power couplers that have been tested with RF power in conditions similar to those specified for ESS. The cavity frequency tuner is also a standard system already used on other cavities for other projects—similar, for example, to those CEA sent to CERN for the SPL [Superconducting Proton Linac] cavities—because we don’t want the expense and risk incurred with introducing a new technology. Our goal is to reach these very high performances, and this is the challenge.”

An Experienced Partner for a Difficult Job

The €104 million WP05 is the largest IKC in value and manpower in the ACCSYS project, and the task is in good hands. IRFU is in the final months of a years-long process of design and production of more than 100 cryomodules for the European XFEL electron linac approaching completion near Hamburg. Many of IRFU’s personnel, along with the lessons learned from the XFEL project, will transfer directly to IRFU’s implementation of the ESS project. The lab’s contribution to the ESS Accelerator is its largest undertaking in terms of resources, with over 80 people already contributing some part of their time to the work.

To build the ESS cryomodules, however, will require different technologies from those built for XFEL, an adapted set of toolings, and the project will entail higher risk in order to reach the unprecedented ESS performance levels.

IRFU began their collaboration with ESS as part of a French pre-construction agreement in 2010, which resulted in the first ESS high-beta cavity prototype in 2012. In 2013, they designed and ordered a medium-beta prototype, and the first of six of these is now undergoing a battery of treatments and tests at IRFU.

“CEA Saclay has been involved it seems since the beginning of the ESS project, and the collaboration with the ESS team in Lund has been great from the beginning,” says Chomaz. “Since we started we have been able to make fast progress and to put the ESS Accelerator on safe ground.”

INFN-LASA and STFC-Daresbury to Produce 120 Cavities

Once performance and quality specifications are shown to be achieved by the cavity and cryomodule prototypes, series production of the cavities will move to INFN-LASA and STFC-Daresbury, who will contract with private companies for fabrication. LASA will produce the 36 medium-beta cavities and STFC the 84 high-beta cavities, and these labs will perform the acceptance testing, including radio frequency (RF) tests in cryogenic conditions.

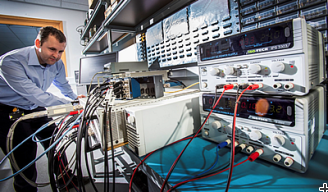

“The high-beta cavities will arrive from industry already processed and ready for performance validation. The team will then assemble the cavities using our own ISO 4 cleanroom and perform several stages of testing,” says Peter McIntosh, Technical Director of the Accelerator Science and Technology Centre (ASTeC) at Daresbury. McIntosh, together with ASTeC’s RF & Cryogenics Group Leader Alan Wheelhouse, and Mechanical Engineering Group Leader Phil Atkinson are managing STFC’s contribution to WP05.

“The key challenge is to assure that appropriate and robust quality controls are in place so that we are able to complete this assembly and testing efficiently and on schedule. One of the primary requirements to accomplish this is to adapt and develop a suitable RF control system as a testing platform, which will ensure fast data collection and monitoring of the cavities throughout the qualification tests.”

Work is also proceeding in Italy. “We are presently working on detailed studies of prototypes in order to finalize the design, the fabrication process and the testing procedures for all medium-beta cavities, and meanwhile preparing the documentation for calls-for-tender for fabrication,” says Paolo Michelato, who is responsible for the INFN-LASA contribution to WP05. The lab will also benefit from recent experience with XFEL.

“LASA has recently produced cavities for the XFEL project, and we will base our work with ESS on the same ‘build-to-print’ concept to prepare the cavities for testing,” explains Michelato. “Each of the 36 medium-beta cavities will be tested in a leading European laboratory before being shipped to CEA for integration with the cryomodule.”

Technical Infrastructure Enables Critical Assembly at IRFU

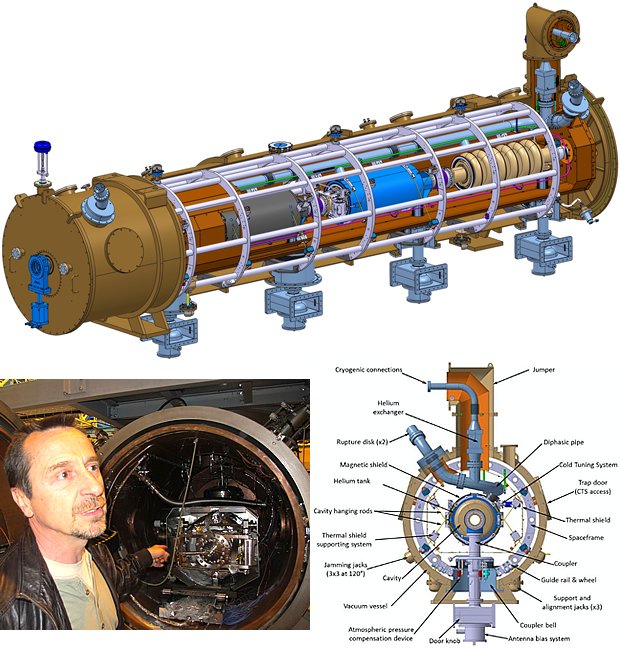

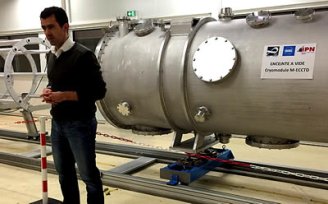

IRFU, meanwhile, will provide and validate all other cryomodule components, including the power couplers, and will assemble the cryomodules in their large ISO 4 cleanroom facility in Saclay. A full elliptical cryomodule contains four cavities and is over six and a half meters long, and the IRFU cleanroom is large enough to accommodate all of the hardware and personnel involved in the complex assembly procedure.

Assembly of the cryomodules is fundamental to the performance of the superconducting cavities. Even a single speck of dust can degrade the performance of a cavity to the point of being unusable, so the process of assembling the cavities and their components prior to sealing the whole unit into vacuum tanks must be done under perfect conditions. It is this final assembly that underlies the critical coordination across the five labs during design, production and testing.

“This is a very important point: we have to work in a large collaboration between ESS, INFN, STFC, CNRS and CEA for the production of the cavities to be assembled in the cryomodules,” emphasises Bosland. “We have to define together at each step what is the configuration of the cavity and what are the precise details of the equipment—how they should be handled, etc. This is discussed through meetings and small workshops including all five teams.”

“Such a collaboration requires daily communication between ESS and its partner institutions,” adds Darve. “The coordination of each deliverable must be defined and verified with the physical and functional interfaces at ESS.”

Beyond the large cleanroom at IRFU, built for the XFEL project, the lab has an additional ISO 5 cleanroom, built in part through a bilateral agreement with ESS, and it is to be used for the delicate assembly of the cryomodule prototypes. IRFU is also equipped to perform the RF power and cryogenic tests on the first three completed high-beta and the first three completed medium-beta cryomodules in order to validate production prior to delivery to ESS. Installation in Lund is scheduled for 2019.

Key Optimisation Challenges Met

One of the limitations on standard linac technology is the amount of RF power that can be transferred to a cavity without degrading overall performance or breaking the power coupler component. IRFU has optimised power coupler technology for ESS to accommodate the outsized requirements of what will be the most powerful linac in the world by a factor of five. Testing at 1.1 MW has proved the new design a success and manufacturing is underway.

Another important advance made at IRFU was to optimise the geometry of the niobium cavities. These are precisely tuned electromagnetic resonators in which a very high electrical field is excited in order to accelerate the proton beam that passes through them. In order to eliminate the risk of exciting dangerous harmonic resonant modes that can create instabilities in the Accelerator’s proton beam, these rogue frequencies, so-called Higher Order Modes (HOMs), need to be kept as far from the beam as possible.

“It is like the string of a guitar,” explains Bosland. “You have the fundamental mode—that is the note we can hear. This corresponds to the harmonic modes used to generate the sound that is characteristic of each guitar. In the elliptical cavity, this harmonic mode is the accelerating one. A perfect world would be cavities without any other resonant modes. But some HOMs may be excited by the proton beam as it passes through the cavity, and we have designed the cavity so that the HOM frequencies are pushed far from the accelerator beamline.”

Forward Momentum is Peaking

All testing necessary to move forward with series production of the cavities, as well as power testing of a full cryomodule assembly, is expected to be complete by the end of this year. The project is now moving quickly.

“The first six medium-beta cavities are being manufactured, the power couplers are being manufactured, the tuners are being manufactured, almost everything,” says Bosland. “And we have received parts of the cryomodule: the ‘space frame’ that will support all of the cavities, the vacuum tank is also here, and the main parts of the assembly toolings have been manufactured and delivered. Follow-up manufacturing is ongoing, and we receive almost everything in early 2016. Then we will assemble the cryomodule in the lab at IRFU.”

The Paris-based labs, IRFU and IPN Orsay (along with the French national neutron source and ESS partner Laboratoire Léon Brillouin), last week had the opportunity to show off their new hardware. The French Ministry of National Education, Higher Education and Research, together with CEA, CNRS and ESS, hosted the 2nd French Industry and Partner Days, featuring more than 160 attendees from science, government and industry.

“The progress at CEA is impressive,” said Lindroos following the event. “We feel confident that with such a competent and experienced partner at our side, ESS will be successful in delivering the Linac on schedule.”