Related News

Copyright 2012 neutronsources.org | All rights reserved. | Powered by FRM II | Imprint / Privacy Policy

Towards energy-saving data storage

A new material retains its special magnetic properties even at room temperature

A new material could become the basis for future data storage devices, since it may enable significant reductions in energy demands in comparison to present-day hard drives. This is a material from the class of so-called magnetoelectric multiferroics, whose distinguishing characteristic is that their magnetic and electrical properties are coupled to each other. Thanks to this coupling, it should be possible to write magnetic bits by means of more energy-efficient electric fields. It has long been expected that this class of materials could serve as the basis for computer memories in the future. The advantage of the newly developed multiferroic material: It exhibits the necessary magnetic properties even at room temperature, and not only — as with most magnetoelectric multiferroics to date — when cooled to very low temperatures, typically minus 200 degrees Celsius. The PSI researchers report their new results in the journal Nature Communications.

Date: 14/12/2016

Source: psi.ch

Researchers at the PSI have created a new material that holds enormous potential for future data storage media. This is a so-called magnetoelectric multiferroic material with a crucial improvement: It retains the necessary magnetic properties at up to room temperature and thus is suitable for everyday purposes.

Magnetoelectric multiferroic materials are extremely rare. In them, the magnetic and electrical properties are coupled to each other. As a result, the magnetic properties can be controlled through the application of an electric field. Electric fields can be generated more easily and efficiently than magnetic fields. When an electric field is applied to magnetoelectric multiferroics, it has an effect on the material’s electrical properties. Through the magnetoelectric coupling, you then get a change in the magnetic properties for free, says Marisa Medarde, lead author of the new study, describing this special class of materials.

Storing data and saving energy

Present-day computer hard drives store data in the form of magnetic bits that are written through the application of a magnetic field. In contrast, storage media based on multiferroics would have several advantages: Magnetic storage could be accomplished through the application of an electric field, which would require significantly less energy; devices would produce less waste heat and thus would also have lower demands for cooling, allowing to reduce the use of fans and air conditioning. Given that cloud computing consumes many trillions of kilowatt-hours of power annually, savings in this area are of great importance.

In nearly all materials, magnetism, as found for example in iron, and ferroelectricity — a particular electrical property of materials — are mutually exclusive. Here multiferroic materials represent an exception: They are magnetic as well as ferroelectric; in addition, these two properties are coupled to each other. Materials that scientists have been able to create up to now, however, show multiferroic behaviour almost exclusively at very low temperatures, such as minus 200 degrees Celsius. The PSI researchers’ new material is an innovation in this respect.

Synthesis, property optimization, and analyses at the PSI

The researchers came up with their new material by custom-tailoring both its chemical composition and the exact production process. They ultimately found that the material with the chemical formula YBaCuFeO5 is suitable, and that it yields the best results when first heated to a high temperature and then subjected to an extremely fast cooling. At high temperatures, the atoms arrange themselves in such a way as to be useful for our purposes, Medarde explains. The rapid cooling essentially freezes this arrangement in place. The underlying method of rapid cooling – also known as quenching – is familiar from the manufacture of especially hard metals and has been used for centuries, for example, in tempering steel swords. The PSI researchers, however, applied much more extreme temperatures:

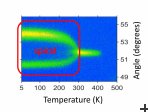

They first heated their material to 1000 degrees Celsius and then cooled it abruptly and rapidly to minus 200 degrees Celsius. After the material is taken out of this cooling bath, it retains its special magnetic characteristics up to and somewhat above room temperature.

The synthesis and property optimization procedure were developed at the PSI, where the materials were also produced and subsequently analysed at two large-scale research facilities, the Swiss Spallation Neutron Source SINQ and the Swiss Light Source SLS. Our new material does not contain expensive ingredients, Medarde is happy to report. And the production method — now that we have worked out the details — is easy to put into practice.

The new material owes its properties to the existence of so-called magnetic spirals at the atomic level. These tiny spirals are responsible for the coupling of magnetism and ferroelectricity. In most materials, magnetic spirals disappear when the material gets warmer than around minus 200 degrees Celsius. The PSI researchers see their main accomplishment in having created a material in which magnetic spirals are stable at room temperature. Even at 30 degrees Celsius, our magnetic spirals were still present, Medarde says.

A relative of the high-temperature superconductors

The material YBaCuFeO5 is in fact not completely new. The compound was actually synthesized for the first time in 1988. Now, however, the PSI researchers’ special fabrication process precisely arranges the iron and copper atoms in such a way that the material acquires completely new properties. YBaCuFeO5 is closely related to yttrium barium copper oxide, chemical notation YBa2Cu3O6+x, a group of superconductors discovered in 1987 that remain superconducting up to relatively high temperatures: Some of them lose their superconducting property at temperatures around minus 180 degrees Celsius — that is, around 200 degrees lower than the spiral order temperature of the new material developed at PSI.

Text: Paul Scherrer Institute/Laura Hennemann

Contact:

Dr. Marisa Medarde, Laboratory for Scientific Developments and Novel Materials, Paul Scherrer Institute, 5232 Villigen PSI, Switzerland

e-mail: marisa.medarde@psi.ch [German, English, French, Spanish]

Original Publication:

Tuning magnetic spirals beyond room temperature with chemical disorder

M. Morin, E. Canévet, A. Raynaud, M. Bartkowiak, D. Sheptyakov, V. Ban, M. Kenzelmann, E. Pomjakushina, K. Conder, M. Medarde

Nature Communications, 16. December 2016, DOI: 10.1038/ncomms13758